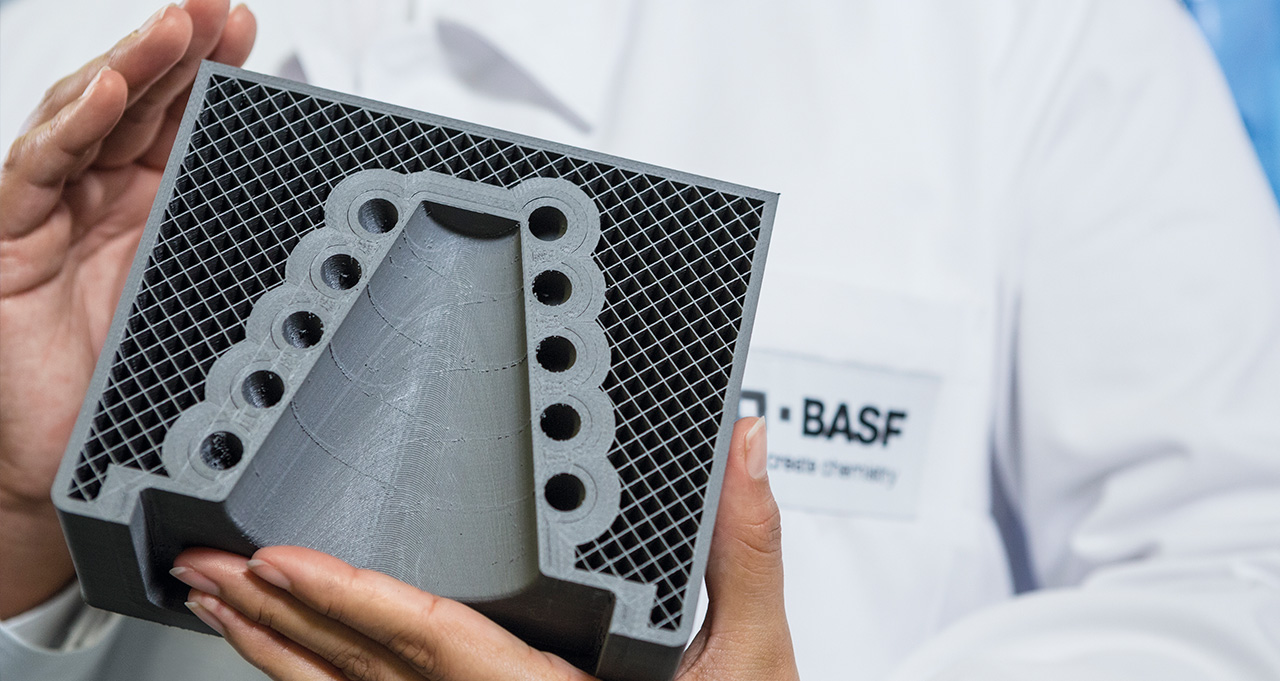

Ultrafuse 316L is an innovative filament for the production of 316L-grade steel parts.

Ultrafuse 316L is an innovative filament for the production of 316L-grade steel parts.

Ultrafuse 316L combines greater freedom of design with a low total cost of ownership.

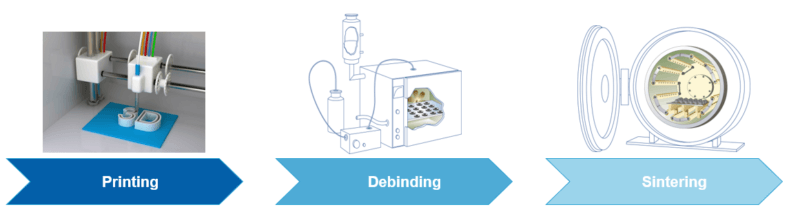

3D-printed parts acquire their final properties, for example in terms of hardness and strength, through a debinding and sintering process developed by BASF, which has emerged as the industry standard.

As a filament, Ultrafuse 316L is 80% stainless steel and has a 20% polymer content which allows for easy printing on many open FFF desktop printers.

In a 3 step process of FFF printing, debinding and sintering you will create a full metal part.

Examples of applications using Ultrafuse 316L:

Ultrafuse 316L is cost-effective because:

Advantages of Ultrafuse 316L:

No customer reviews for the moment.