DriftDog - Orthopedic aids for animals thanks to 3D printing

DriftDog is a company specialized in the production of customized trolleys, other orthopedic aids and technical solutions for animals with disabilities. They deal with the design, construction and customization of each product according to the needs of the "4-legged" customer (not only 4), providing experience in 3D printing, scanning and 3D modeling to offer services for the veterinary sector.

Francesco Messina, 3D modeling technician and founder of DriftDog, talks about the experience of his company.

"We were looking for a solid, reliable and technologically advanced printer we came across the Raise3D Pro2. After chatting online with other Raise3D users and testing ideaMaker, immediately intuitive and complete 3D printing slicing software, we decided to purchase one (for now).

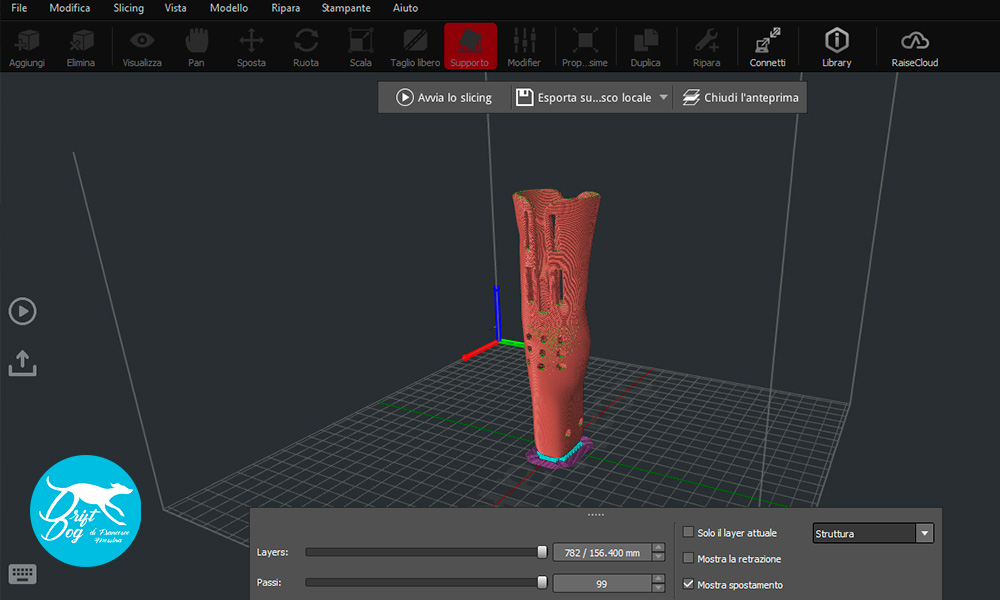

Prosthesis component in the slicing phase with ideaMaker

DriftDog applies 3D printing, 3D scanning and 3D modeling techniques to most of its activities. From rapid prototyping and subsequent production of new components for our trolleys, to the printing of jigs which are essential for certain processes.

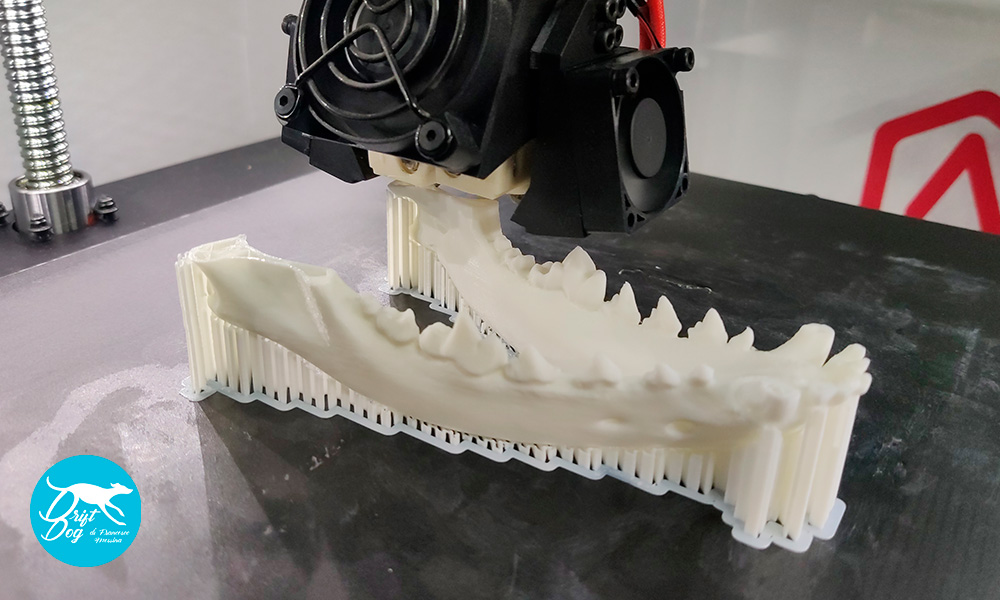

TPU 3D printed prosthetic component

We study and manufacture, in cooperation with orthopedic veterinarians, orthopedic prostheses, braces, 3D printed immobilizers!

Furthermore, we 3D print anatomical models for veterinary training and practise.

Among our works made thanks to 3D printing:

- protective helmets for dogs with hydrocephalus problems

- reconstruction of the carapace of a struck turtle

- artificial paws for birds

Canid mandible during 3D printing

Without 3D printing this would have been impossible.

We should have relied on the components we commissioned to external companies, in order to obtain a functional prototype, with the risk that for any modification we would have wasted precious time and thousands of euros.

In order to get the finished products, we should have used traditional methods, spending large sums on machinery that we would have used only for that specific process.

Right from the start, our Raise3D Pro2 brought practicality to our reality: we can print an infinite range of technical materials. Thanks to the double extruder we save time by printing water-soluble supports, thus obtaining an even cleaner result.

The double extruder is useful for 3D printing end-use parts, customized with our logo in two colors; thanks to the large printing area we have no limits in processing, we are almost always able to print components in one piece.

Example of a educational anatomical model of a canid skull in 1: 1 scale

I can't think about the future of DriftDog without the use of 3D printing!

Now we are working to be able to offer veterinarians, in a very short time thanks to 3D printing, models for surgical planning.”

In Same Category

Related by Tags

- 3D printing for the Education and STEM disciplines: the FabLab Poliba experience

- Fireproof additive manufacturing: the benefits of flame retardant materials in modern industry

- Raise3D Announces the Launch of the DF2 Solution at Formnext

- 3D printing and footwear: the FuSa shoe

- La stampa 3D nel settore farmaceutico

Leave your comment