![]()

![]()

![]()

![]()

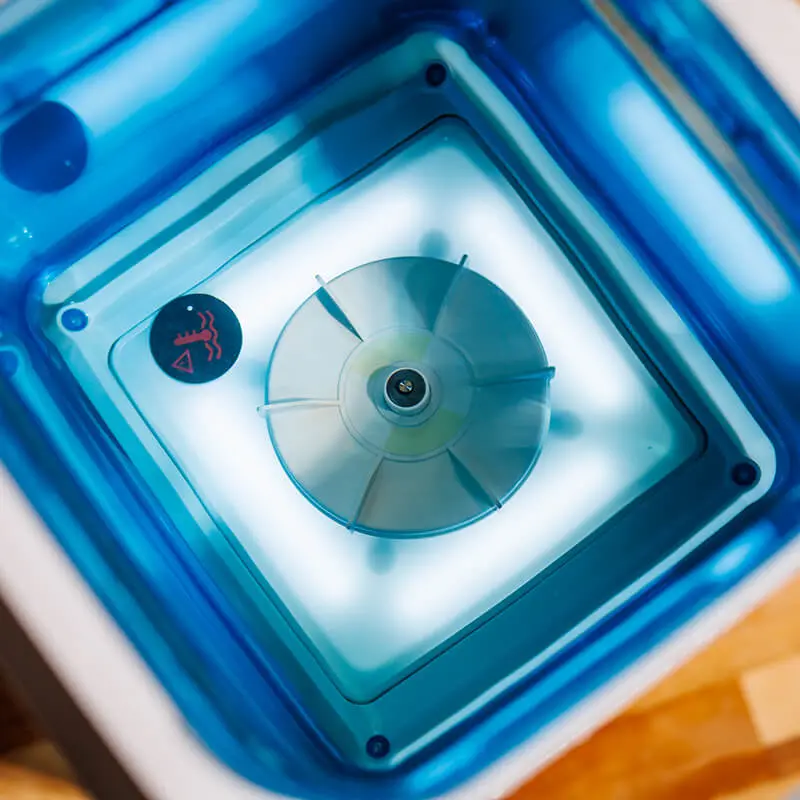

High-speed water circulation driven by a magnetic rotor removes PVA up to four times faster than motionless water, even from hard-to-reach cavities. So you have your parts post-processed and ready to use as soon as possible.

The Ultimaker PVA Removal Station requires only a few minutes of operator time per print, with minimal maintenance needs. Just press the start button, leave it to do its job, and collect your print when it's ready.

Choose 100 or 225 RPM circulation depending on the fragility of your part. Every two minutes, the rotor changes direction to push water evenly against the model.

A rinsing basket keeps your print in place and completely submerged while dissolving, then lifts up for mess-free draining and print removal.

A transparent, illuminated container lets you easily follow the PVA removal process and see when your part is ready. Plus, a saturation indicator shows when to refresh the water.

| Properties | Container volume | 13.7 L |

| Maximum part size (XYZ) | 200 x 230 x 165 mm | |

| Supported materials |

Optimized for: Ultimaker PLA and PVA Also suitable for PETG, Tough PLA, Nylon, CPE in combination with PVA. |

|

| Supported solvents | Water | |

| Rotational speed |

225 RPM (Normal) 100 RPM (Low) |

|

| Operating sound |

< 50 dBA |

|

| Physical dimensions |

Dimensions (with handle upright) |

303 x 325 x 374 mm 303 x 325 x 528 mm |

|

Net weight |

6.35 kg |

|

|

Container weight (empty) |

4.2 kg |

|

|

Shipping box dimensions |

400 x 400 x 500 mm |

|

|

Shipping weight |

8.5 kg |

|

| Ambient conditions |

Operating ambient temperature |

15 – 32 ºC |

|

Non-operating temperature |

0 – 32 °C |

|

|

Relative humidity |

10 - 90% RH non-condensing |

|

| Electrical requirements |

Voltage |

100 – 240 V AC |

|

Frequency |

50 – 60 Hz |

|

|

Power |

38 W |

|

| Warranty |

Warranty period |

12 months |

No customer reviews for the moment.