3D printing in the railway sector

2050.AT, a division of the Transmashholding/Lokotech Group of Companies, the largest Russian manufacturer of railway equipment, uses a Print Farm of Raise3D 3D printers to produce functional parts and prototypes for locomotive facilities and transport engineering enterprises.

Igor Konovalov, Technical Director of 2050.AT, and Andrey Stepanov, Manager of their additive technologies projects, shared their experience of using 3D printers in transport engineering.

Raise3D: Ctrl2GO Group of Companies, which includes your division 2050.AT, is creating a digital platform for the development of 3D printing. In what projects and for what purposes do you use additive technologies?

2050.AT: First of all, for the production of functional component parts and prototypes for locomotives, tractor plants, etc.

We visit depots and locomotive repair plants, and on the basis of these visits prepared a list of scarce pieces and other products with delivery problems. This could be discontinued component parts or products with lost documentation. Then we scan the part or create a 3D model in a special program and reengineer it, if necessary. Later, we print this component part. If it needs painting, we give it to the paint shop and then make improvements where necessary.

We have recently made a sleeper transfer (“strelnik” in Russian), which is intended for transfer rail tracks, using 3D printers.

Cover for the video mirror on the Ivolga commuter train

Spare parts for tractor plants and agricultural machinery

Raise3D: And what functional component parts do you print?

2050.AT: We print parts for traction rolling stocks. These are interior parts that are a kind of switch. For the driver’s cab, we print handles, covers, and caps. Though, we can’t print anything that isn’t agreed upon with Russian Railways. All changes to the part design or the use of other materials not specified in the design documentation have to be agreed upon, and this process takes more than one month.

Raise3D: How long have you been implementing 3D equipment in your work? Do you use only these desktop printers (such as Raise3D) or other industrial equipment as well?

2050.AT: Originally, we bought 4 Raise3D Pro2 printers before the New Year 2019. We liked them and bought another 16 printers in spring. Now, we have 20 Raise3D printers. In general, we planned to have 50 printers, but with the current workload, 20 printers are sufficient for us. We will get more when we need it.

We did not consider other industrial printers, because they have a completely different price range.

“Raise3D is just excellent in terms of the price-quality relationship.”

3D scanners are also used in our company. It’s very simple: we scan the component part, engineer it or leave it without changes, and then print it.

Raise3D: Why did you choose FDM/FFF technology?

2050.AT: At the moment, this is one of the most widely available additive technologies. We are satisfied with its print quality. Now we are making a snowmobile prototype for Ruskaya Mechanika. We have already done two of them, and now this company wants to launch a batch of goods for their dealers so that they can show them on test drives.

Raise3D: On your web-site, we saw the following research data: if the number of parts of one item does not exceed 1,000 units per year, it is advantageous to produce them using additive technologies. How did you carry out such tasks before 3D printing was introduced?

2050.AT: Such tasks were traditionally performed by an ordinary locksmith in a locomotive facility. He would sharpen a wood component part with a file or chisel, then measure the part, and, if it didn’t fit, sharpen it again and so forth. What I mean is everything used to depend on the worker.

For example, the production of a tractor is started at the plant. To make a bridge, we primarily make a press mold, then cast it in metal. Some pieces don’t fit. And remaking of the press mold in the traditional way will take another 4 months.

With 3D printers, we will print press molds with all adjustments and changes in 2 weeks maximum. The manufacturing speed of products, equipment, and prototypes has increased significantly.

There is one more thing. When locksmiths do everything manually in a locomotive facility, it takes time. Time means locomotive downtime and, therefore, a lot of money.

Let’s not forget that the human error problem is also solved due to 3D printers. There is increasingly less highly qualified specialists in the workshops. Automation of these processes enables us to solve problems with deliveries of rare and small-scale details and to save quite a sum in the process.

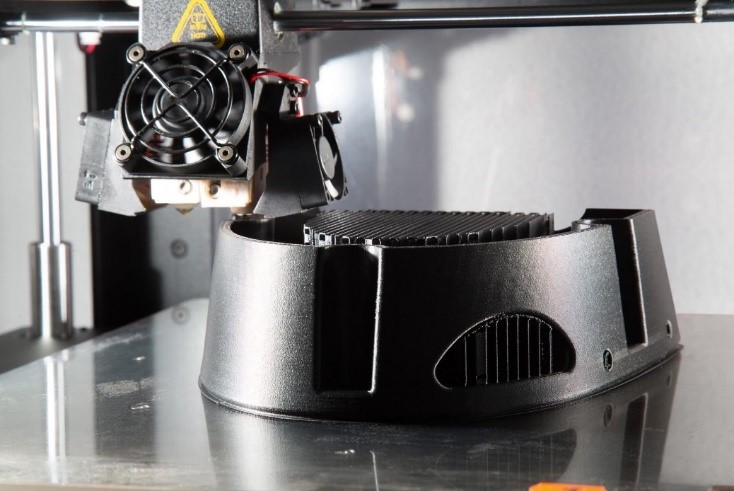

3D printing of cabin interior components

The application scope of printers in the driver’s cabin is huge. There are lots of details and buttons.

For instance, if a switch broke in the locomotive, as they are periodically broken or lost. Manufacturers do not fabricate individual switches, so you have to buy a whole set of them to replace one piece. But we can print the necessary detailed piece using our 3D printer.

There’s an inspection by the Russian Railways Technical audit center, which verifies repaired locomotives. All repairs shall comply with design documentation. If something is missing or is missing necessary technology, the locomotive fails the verification and the Center does not sign the required documentation. This again means downtime and money lost.

Raise3D: Why did you choose Raise3D? What was important for you in the printer? What are its pros and cons, in your opinion?

2050.AT:"First of all, there are no other manufacturers with software like ideaMaker and with such a convenient cloud platform as RaiseCloud."

All our printers are connected to the cloud. We have not seen such high-quality alternatives in the products of other manufactures.

Thanks to RaiseCloud, printers make component parts on weekends, while we follow the process through the remote mobile application.

We haven’t inserted a USB drive into the printer for ages. Now we send everything to the printer through Wi-Fi.

“As for ideaMaker software, I consider it the best one and the main thing is that it ‘s constantly updated and improved.”

To date, there are few, practically none, with such reliable and high-quality printers on the market.

“We are very pleased with the support and guidance provided by Raise3D, their willingness to help and solve problems.”

We wish Raise3D released a bigger printer. We will be their first customers.

We have 150 depots, 10 repair plants, and 10 production plants, so the segment is huge.

Flexibility in Material Choice

Part for locomotive, Air Hose Bracket.

Raise3D: What materials do you mainly use for printing?

2050.AT: We use all the materials that exist on the market, all that can be melted in the extruder. These are mostly composite plastics, of course, and ordinary ABS, and, less often, PLA.

We recently did press molds from ABS for Tupolev (PJSC. A leading Russian enterprise in the field of design, production and after-sales support of missile carriers and bombers and special-purpose aircraft).

They needed a mold on which could be stamped from thin aluminum with a load of 300 kg per cubic centimeter.

We also have our own material – polypropylene.

Raise3D: Could you tell us more about your material?

2050.AT: This is a black and white glass-filled polypropylene, adapted to Raise3D printers, which we developed together with Sibur. It can withstand very heavy loads. In the near future, we plan to buy a line for the production of filamenti. We have a lot of plans and tasks and are trying to optimize the production in every possible way, to ensure the fastest and highest quality production process, of course, using 3D technologies.

In Same Category

Related by Tags

- Bambu Lab X1E: multifilament 3D printing in industrial applications

- 3D printing for the Education and STEM disciplines: the FabLab Poliba experience

- Fireproof additive manufacturing: the benefits of flame retardant materials in modern industry

- Raise3D Announces the Launch of the DF2 Solution at Formnext

- 3D printing and footwear: the FuSa shoe

Leave your comment