Gli uffici e il magazzino di Crea3D rimarranno chiusi dal 10 al 25 Agosto 2024. Gli ordini effettuati in queste date verranno elaborati a partire dal 26 Agosto 2024.

Target applications

New hardware features

Materials

When you need to keep operations running, Factor 4 can help simplify factory processes and reduce human-related inconsistencies. It facilitates operations with direct dual material extrusion, support for engineering materials, and onboard print process reporting to achieve unrivaled predictability and minimal variance.

The ability to accurately reproduce functional parts in a wide variety of engineering materials accelerates testing and innovation. Factor 4 is a low-emission, low-maintenance platform that’s safe to leave unattended. Stay in full control with over 400 Cura settings and in-depth part validation tools.

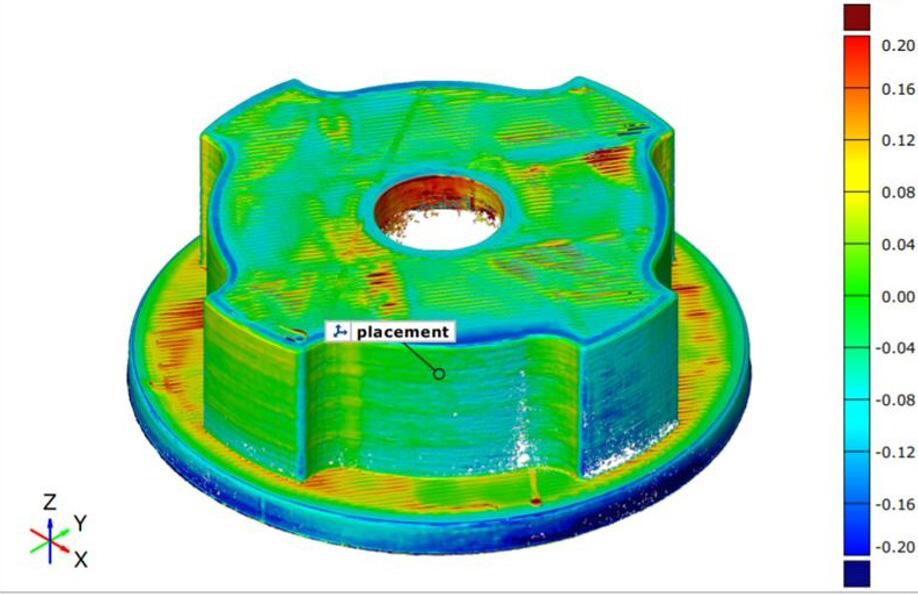

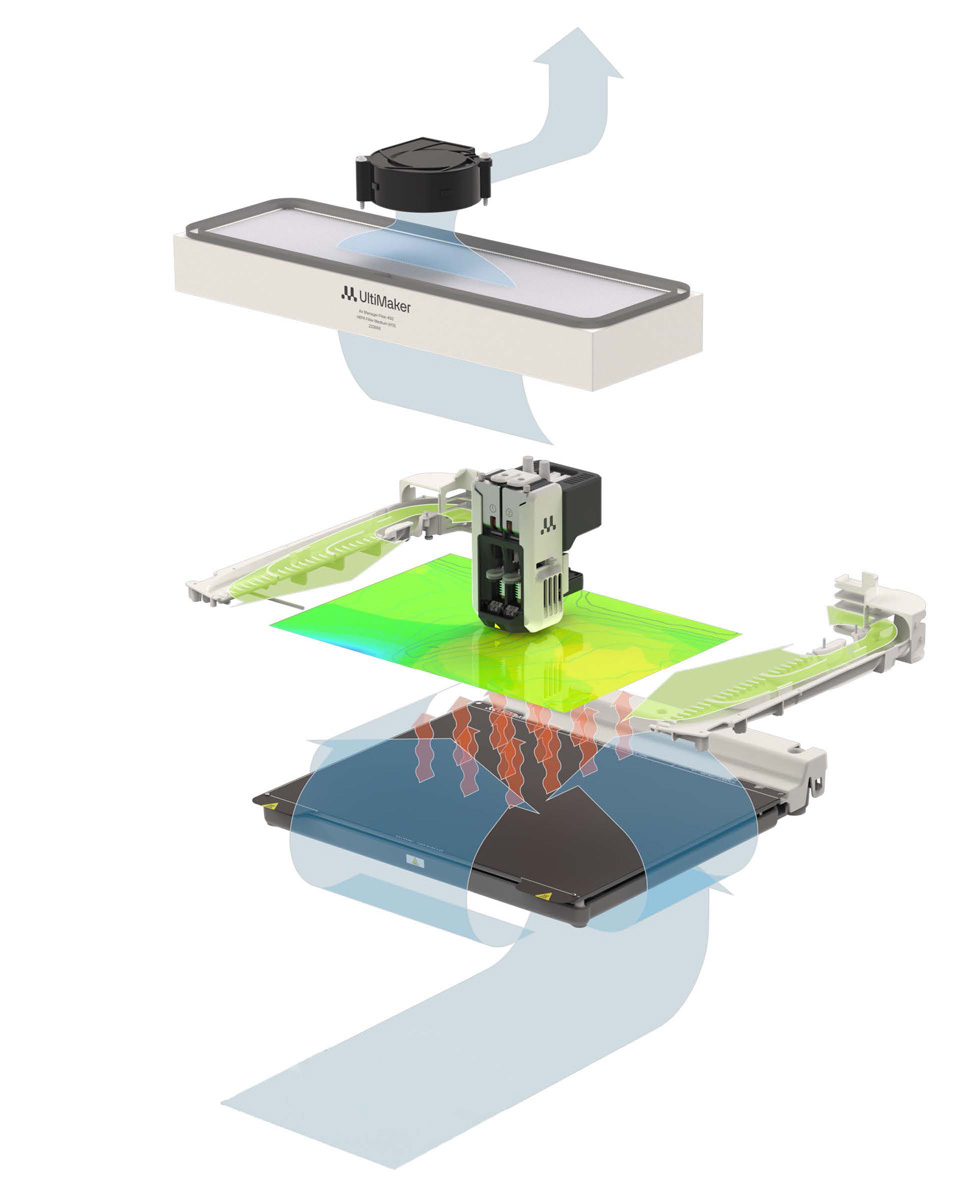

Factor 4 delivers predictable, verifiable part quality for distributed production. The less than 10% variance in extrusion rate and mechanical properties, plus the repeatable dimensional accuracy batch after batch, is a combination of the H-bridge gantry, closed loop feed control, and uniformly controlled build plate temperatures – with a maximum variation of 5 °C across the X and Y axes.

UltiMaker PPS-CF is a new hightemperature composite for Factor 4 that can replace complex steel parts. Its heat deflection temperature is greater than 230 °C. It’s chemical resistant and flame retardant (UL94 V0), making it a versatile choice for demanding applications.

Flexible materials down to Shore 70A means you can reliably protect parts from damage and create gaskets, seals, and shock absorbers.

A wide range of high-performance and certified material properties opens up a huge range of new 3D printing applications on Factor 4.

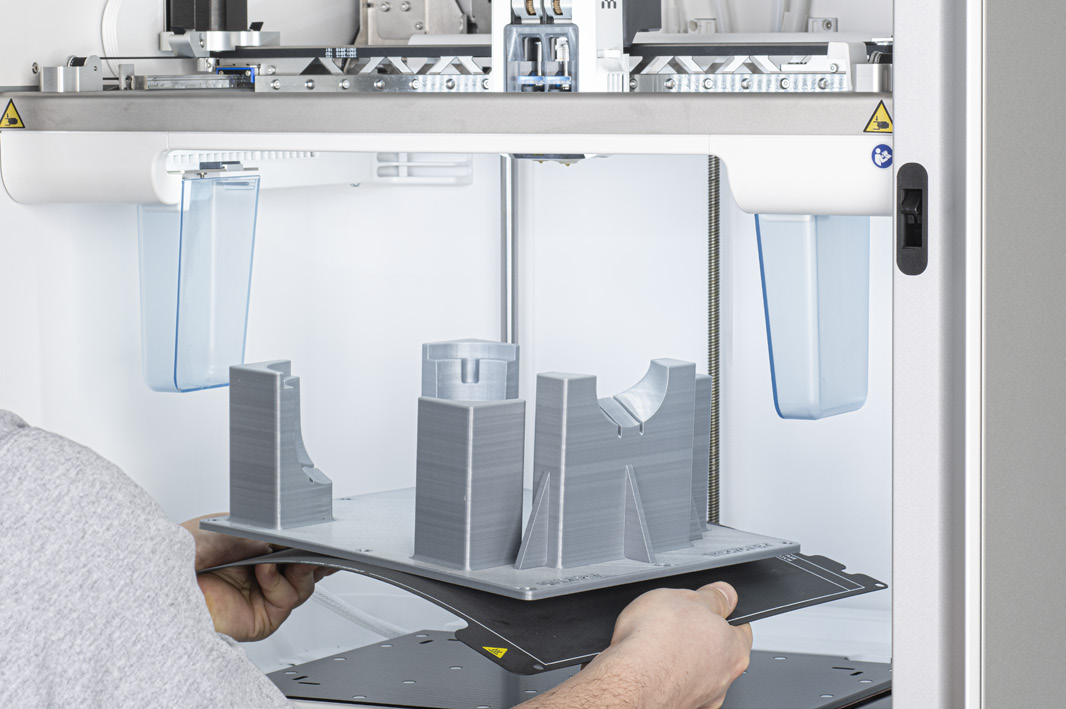

3D print with confidence across every millimeter of the 330 x 240 mm flexible build plate. And quickly remove parts thanks to its PEI coating.

We have verified dimensional accuracy within ±0.2 mm or ±0.2 % nominal length over the full printer build volume using PPS CF, PET CF, Tough PLA, and PETG.

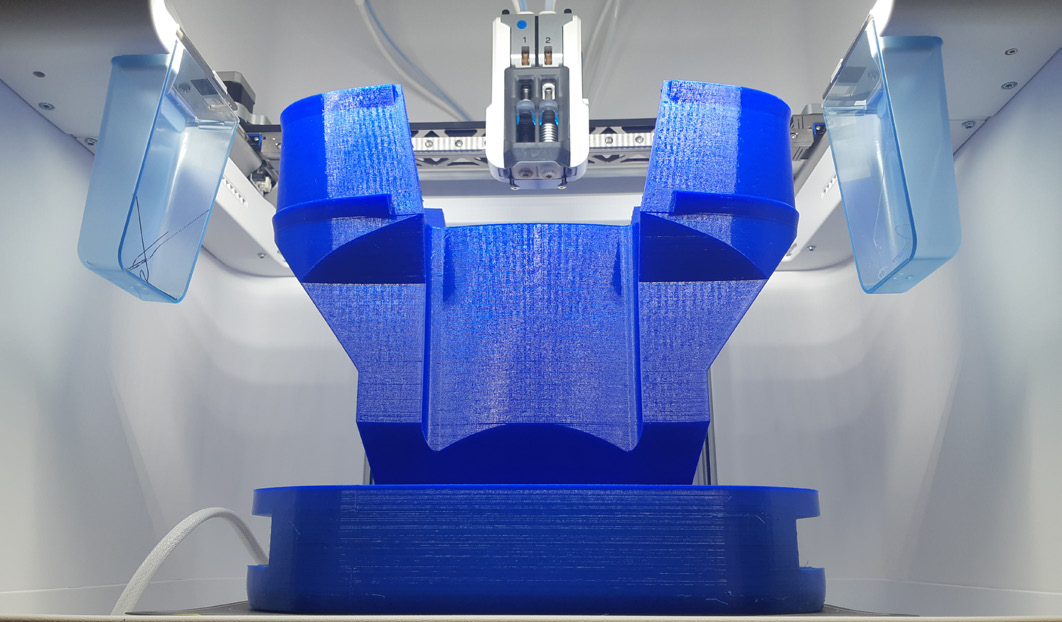

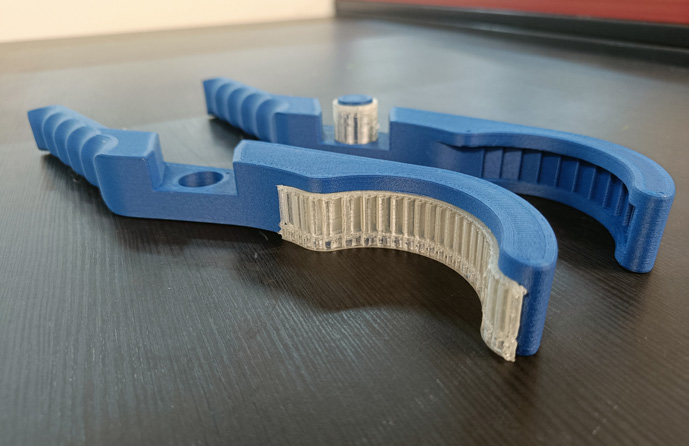

Leverage the full power of additive manufacturing with fast dual printing capabilities for complex geometries and multimaterial parts.

The combination of the all-new H-bridge gantry and direct drive extrusion print head allows high-speed movement and positional accuracy of ± 0.2 mm or ± 0.2 % of the feature’s nominal length with UltiMaker Verified Materials. This results in best-in-class dual material printing speeds so that you can quickly create the flexible or strong parts you need.

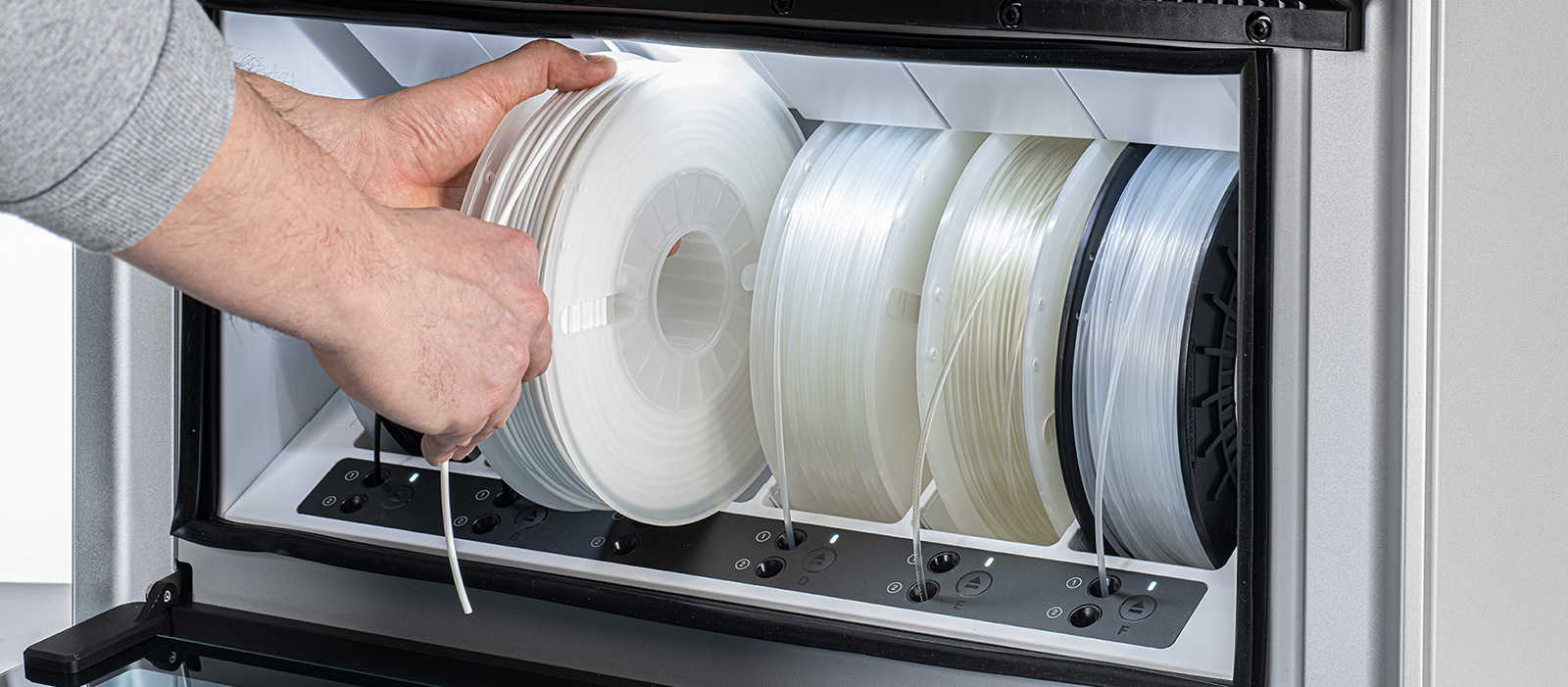

A new, integrated, automatic material handling system reliably manages your spools so you don’t have to. The internal chamber is kept at less than 10 % RH in office conditions, so you can keep up to 6 kilograms of filament in perfect condition for back-to-back print jobs.

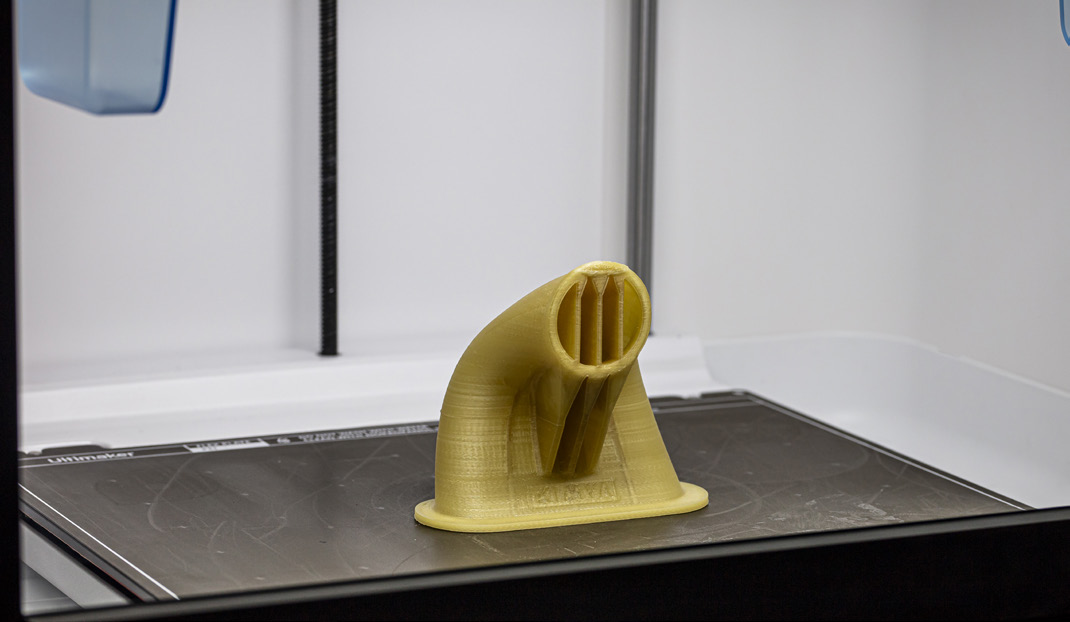

UltiMaker Factor 4 raises the temperature up to 340 °C using the HT print core.

This means that you can now 3D print higher temperature-resistant and durable materials with more confidence.

The temperature within the fully enclosed build volume is also controlled up to 70 °C, with a heated bed up to 120 °C, ensuring optimal material-specific processing conditions and consistent part quality wherever the 3D printer is located.

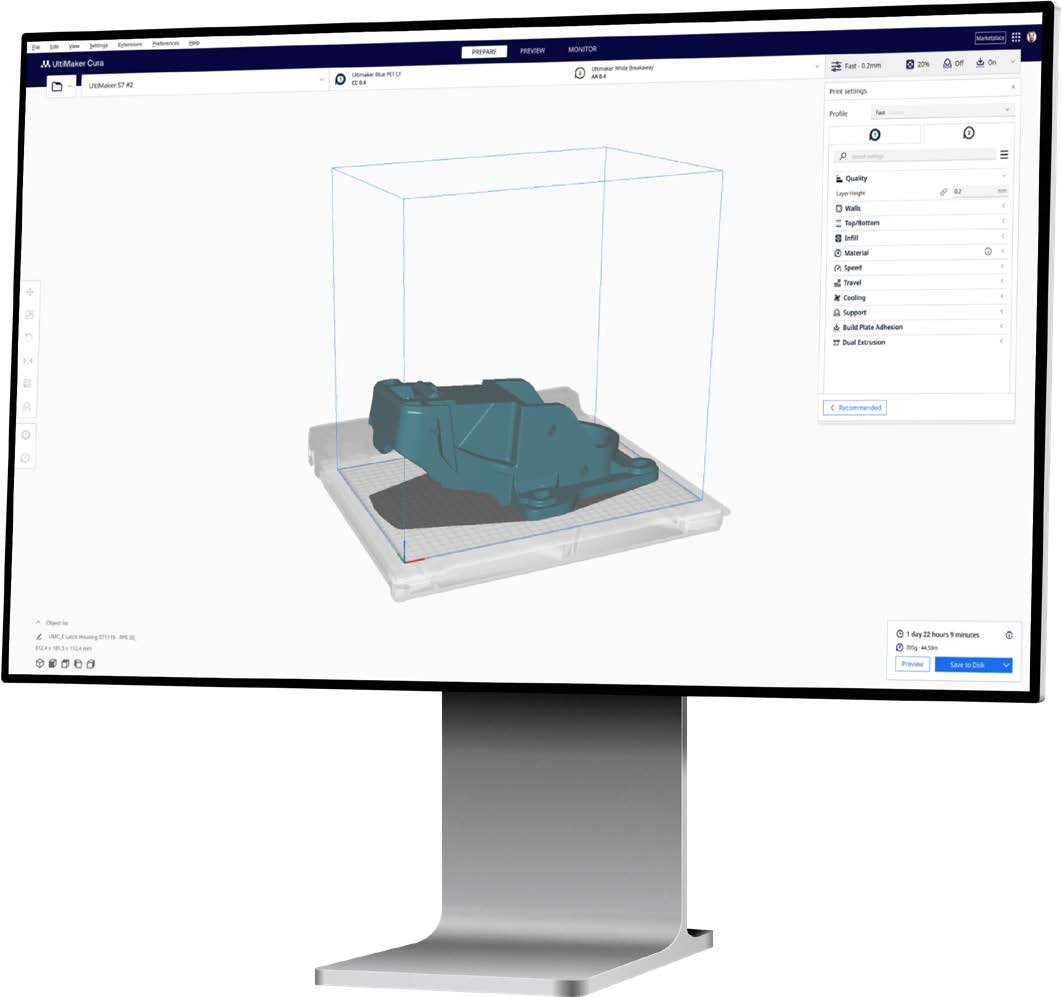

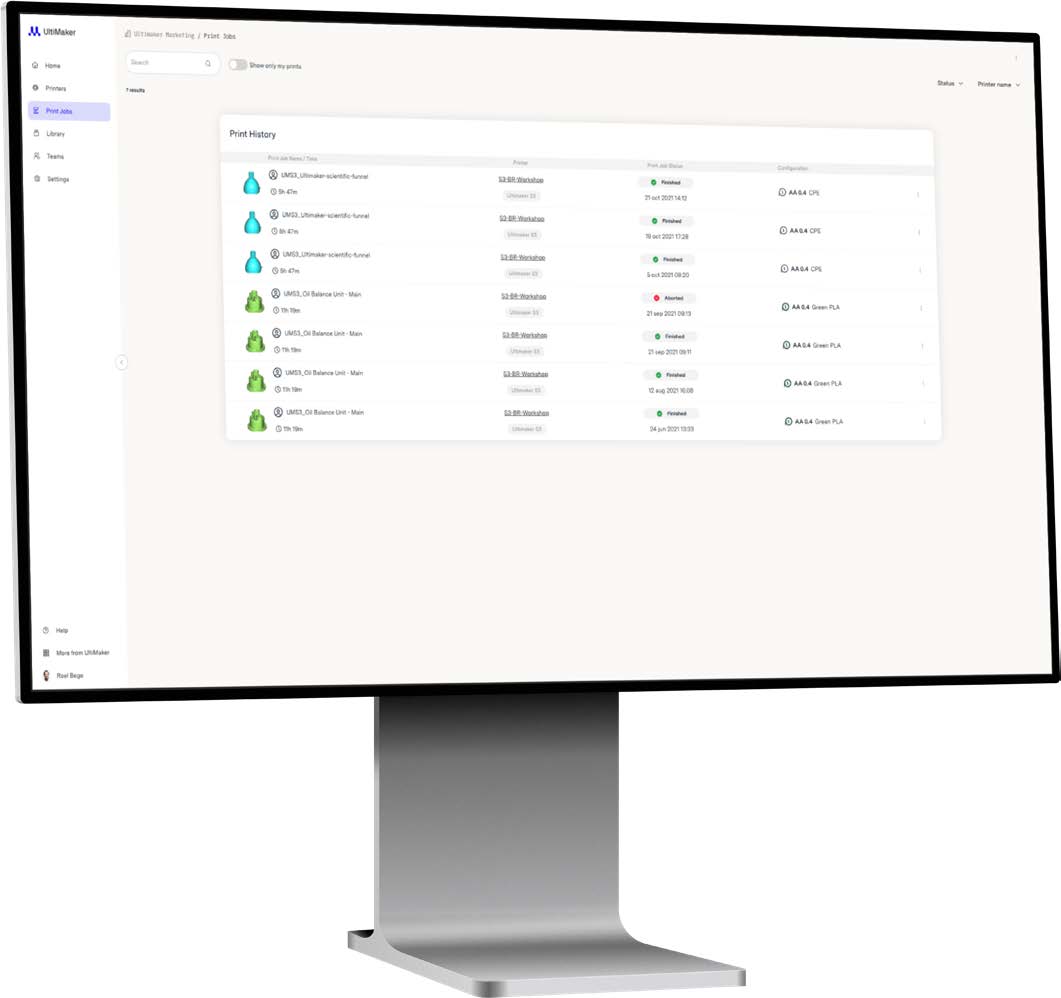

UltiMaker Cura and Digital Factory work together with Factor 4 and UltiMaker materials to provide an easy, secure, and reliable workflow - from 3D model to printed part.

Our software leads the AM industry with its powerful slicing engine. A variety of file types including native CAD files can be directly imported and quickly sliced with pre-tuned application intent profiles. Cura also features:

With shared workspaces, assigned roles, and file management using the digital library, coordinating your printing schedule is simple. The live HD camera feed on every Factor 4 combined with progress and status updates makes it trivial to handle multiple prints on multiple printers with zero downtime. Digital Factory also includes:

No customer reviews for the moment.